"What is the typical base oil viscosity of a grease for […]

"What is the typical base oil viscosity of a grease for high-speed bearings?"

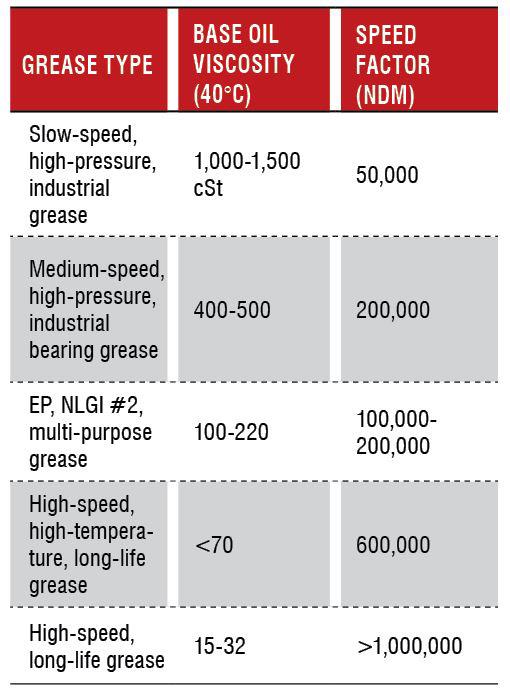

The base oil component of grease is what provides the essential separation between two surfaces that may come in contact. Therefore, selecting the correct viscosity is very important. One common way to identify the appropriate viscosity is to first determine the speed factor, which is calculated from the bearing speed (revolutions per minute) multiplied by the pitch diameter (if using the NDm method). When the bearing speed increases, the speed factor also increases. If the bearing speed and speed factor increase, the corresponding viscosity for the application will need to decrease.

As seen in the chart below, a base oil viscosity of less than 70 centistokes (at 40 degrees C) is ideal when approaching a speed factor of 600,000. Since high-speed applications tend to have higher temperatures and thus a shorter grease life, the overall grease properties should be designed to withstand these conditions.

The operating viscosity will depend on the actual operating temperatures. With a speed factor of 400,000 and operating temperatures less than 60 degrees C, a minimum viscosity grade of 15-22 may be required. If the operating temperature is closer to 100 degrees C, a minimum viscosity grade of 32-46 may be necessary. More viscosity is acceptable and may contribute to better protection as long as it isn’t excessive and doesn’t lead to extreme temperatures, a premature breakdown of the grease or a bearing failure. Therefore, a viscosity grade of 68 or higher is frequently selected in these applications.

The thickener type, concentration and NLGI number must also be considered. Because of the many factors to consider, it is not unusual to see greases labeled specifically for high-temperature or high-speed applications. Again, this conveys that the grease has been formulated to operate in these conditions. For example, a grease’s structural stability, oxidation resistance, wear and corrosion protection, etc., are all very important for high-speed applications.

Because higher temperatures are expected in these applications, a synthetic base oil and an advanced additive system are often recommended, particularly if it is a critical bearing. Depending on the manufacturer, different thickeners may be appropriate, including polyurea and lithium, if they have good channeling characteristics and don’t contribute to excessive heat generation as the bearing speeds up.

Finally, keep in mind that grease generally will not last as long with higher speed bearings. For a healthy bearing life, it’s best to replenish with grease more frequently.

To receive updates from Xin Gang, simply complete your details and let us know what you want to hear about.